industry-news

Local Efficiency Insulation Rebates

May 11, 2021

Hearing protection at work is serious business. 87% of cases involving occupational hearing loss are reported among workers in the manufacturing sector, according to the CDC. Most of the dangerously loud noises associated with the manufacturing industry are related to the mechanical processes that take place in facilities, from piping systems to automated machines to HVAC sounds. Beyond hearing loss, prolonged exposure to excessive noise can cause other problems like increased accidents and stress levels.

OSHA requires that employers provide protection against noise exposure when workplace noise reaches certain decibel levels. All employers should have a thorough understanding of the noise conditions in which their employees are working and understand how much protection they legally need to provide.

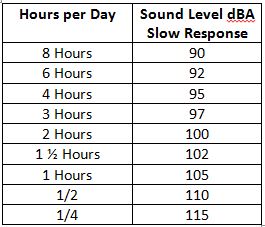

This table shows the allowable sound level decibels for given time periods. Employers are required to provide noise protection if their staff is exposed to continuous noise for the lengths of time and decibel levels shown below.

One of the easiest and most effective ways to reduce mechanical noise in the manufacturing industry is to insulate mechanical systems. Sound attenuation with insulation can require both standard and specialized insulation materials to encase or enclose the noise source, forming a sound barrier between the source and the surrounding area.

Using mechanical insulation as a sound-limiting material has the following benefits:

Mechanical insulation is an effective solution for providing acoustic barriers, reducing noise, and dampening vibration. In the manufacturing industry, where adhering to OSHA standards of occupational noise exposure is extremely important for the health and safety of workers, insulation can have a significant impact on the noise level in a facility.