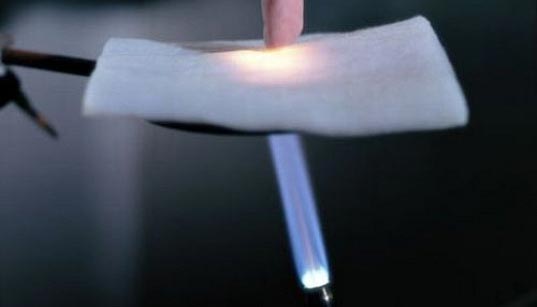

Aerogel

Aerogels are created by combining a polymer and a solvent to form a gel, and then removing the liquid from the gel to be replaced with air, resulting in one of the most effective insulation materials in existence.

Common Applications

Aerogel insulation is well-suited for extreme high and low temperatures, places where space is extremely limited, and any water applications, including steam piping and in refineries. Other key applications include:

- Steam distribution

- Chemical processing

- Cryogenic LNG piping

- Power generation

- Aerospace and defense systems

- Subsea industry

- Construction and building insulation

Aerogel Insulation Properties

- Service temperature up to 1,200F for Pyrogel products

- Nominal thickness of only 5 or 10 mm depending on product and application

- Extremely low thermal conductivity (performance ranges between 14.5-21 mW/m-K)