Weidmann Electrical Technology

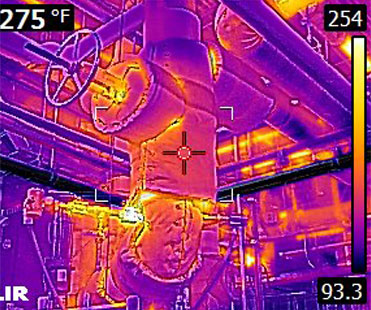

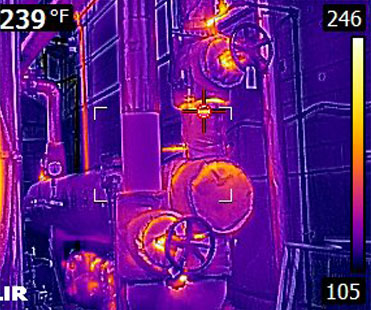

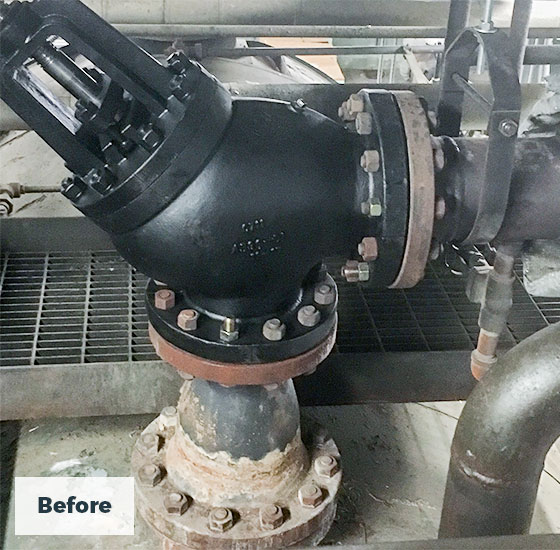

Weidmann, a global leader in the design, development, and operation of products and services in the energy sector, approached NCMI after they underwent an energy audit from Efficiency Vermont. Although pipe covering had been installed previously, Efficiency Vermont knew there was more efficiency to be gained through the insulation of gate valves, PRVs, steam traps, strainers, and flanges.